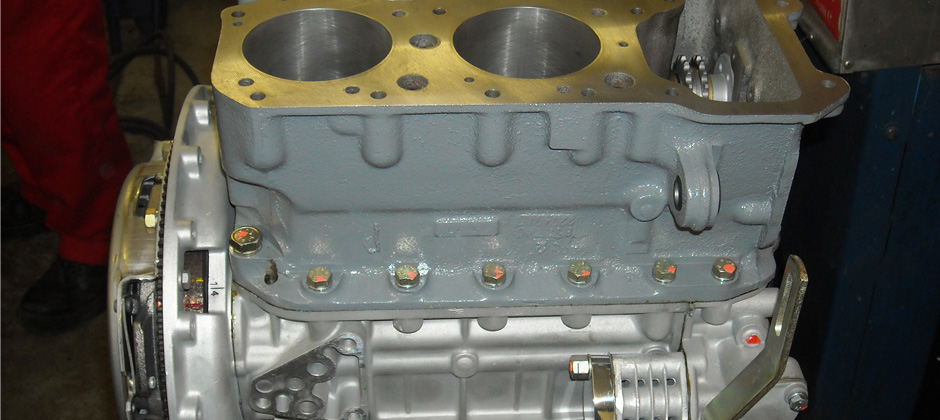

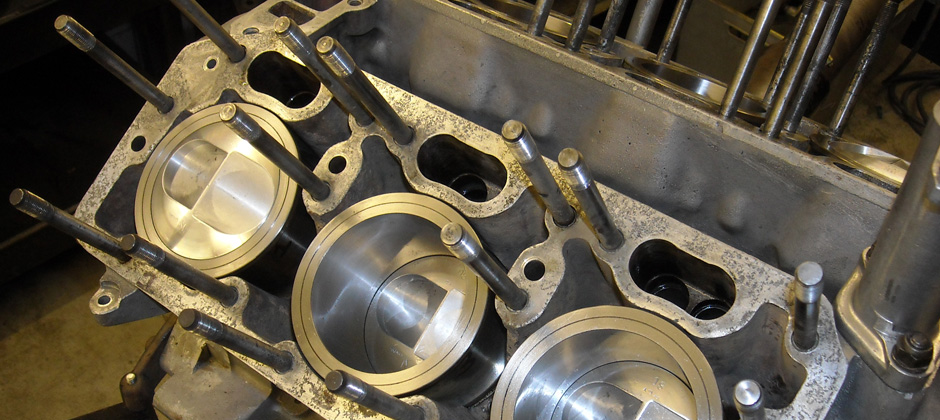

We have all the facilities to carry out a full or partial engine rebuild in-house, including majority of engine machining such as re-boring, fitting valve guides and seats, and some balancing, oursourcing only a few of the most specialist work which is entrusted to experts in that field.

Whilst many people want their engines rebuilt to the standard factory specification, a number of owners opt for an uprated or enhanced specification, either a fast-road specification or a higher level of competition tune suitable for circuit racing or rallying. As part of this works, bespoke parts often have to be designed and manufactured, much of the design process is often done in house. Note: contrary to popular opinion, uprated components do not necessarily make the engine ‘better’, merely more suitable for its intended role.

The oldest engine we have rebuilt was from a 1901 Lanchester which was done for the Jaguar Daimler Heritage Trust, a curious flat-twin engine, with twin contra-rotating crankshafts. Each piston had three connecting rods, a main connecting rod to one crankshaft and two thinner rods to the other crankshaft. Lanchester went on to invent and pioneered the twin balancer shafts system that Lancia and Fiat used in the later 16v versions of the Lampredi twin-cam engine some 90 years later.

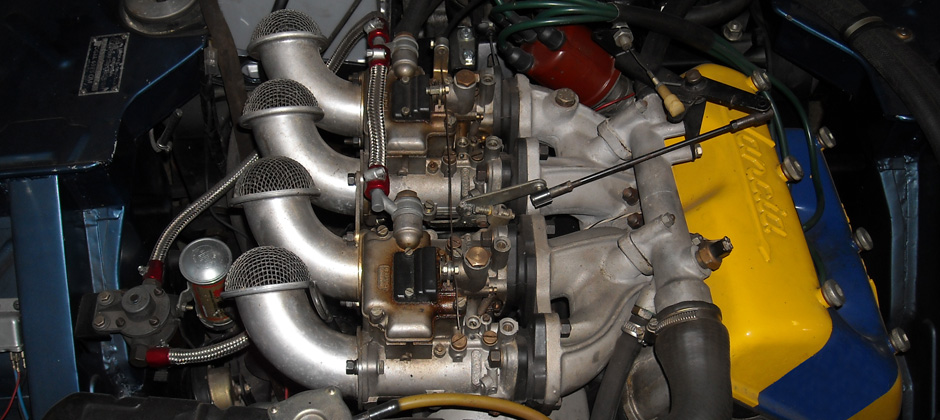

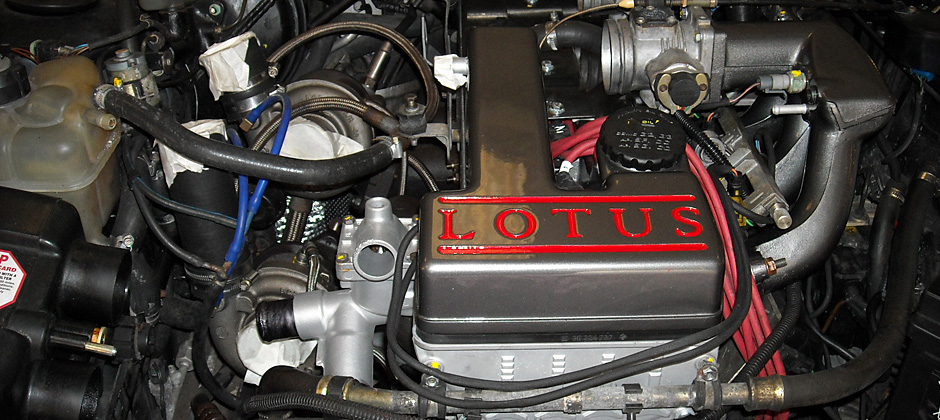

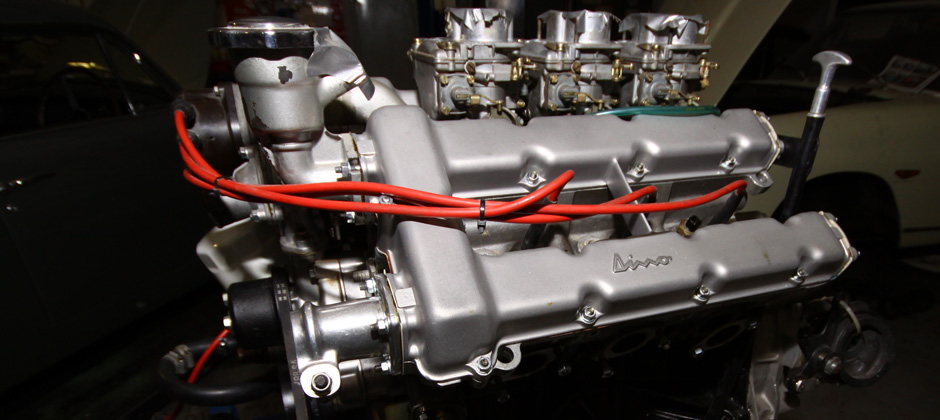

As well as this we have built or worked on many Lancia engines from the 1920’s up to the more modern versions, with many variants of Aurelia, Aprilia, Appia, Flaminia, Flavia/2000 and Fulvia engines, also the Dino V6 used in the Stratos, Fiat Dino and ‘Ferrari’ Dino 246GT but we have also rebuilt Maserati engines, Lamborghini V12 engines, Ferrari V8 and V12 engines as well as Hispano Suiza, Packard straight eight, Alfa Romeo, Bristol, Ford, Rover, Fiat, Vauxhall, and as part of our single seater racing programme, have built Toyota, Vauxhall and Mugen-Honda F3 engines, as well as converting from fuel injected engines to carburettor and vice versa, the latter requiring custom made throttle bodies with the fuel and ignition mapping carried out in house.

We have an engine testing fixture which allows us to run an engine out of a car to make sure that temperatures and pressures are as expected, there are no unexpected leaks and allows us to put several heat cycles through the engine which some constructions of head gaskets require as part of the cylinder head tightening process.

We can arrange for the engines power / torque to be measured on an engine dynamometer if required, or is the car is mobile a chassis dyno can be used (commonly known as a rolling road).

We regularly receive engines from overseas for strip down and rebuilding.